Harvesting Grain Maize

The quality characteristics that industry operators (or farmers) look for in grain maize depend just as much on the grain drying and storage conditions as they do on the crop stage at the time of harvest. With grain maize, farmers will look for optimum economic results, while watching over the plants’ sanitary condition.

Striking a Balance Between Quality and Quantity

Producers in many countries choose to do most of the crop’s drying while it is still standing, the reason for it being their often insufficient drying capacities. The method has both benefits and disadvantages, as on the one hand, it eliminates a cost and reduces the crop’s environmental footprint, yet on the other hand, it compels one to choose hybrids that may be too early for the local climate and thus deprive the producer of a significant yield potential (up to 5-7 quintals per 100 FAO units).

Moreover, this involves using hybrids that are mostly known for their mechanical vigour, their dry-down rate, and not necessarily their agronomic qualities per se.

A good compromise is probably harvesting at about 22-25 percent moisture. This allows one to make good use of the climate potential, harvest before any losses occur (due to lodging or disease), and rely on natural drying. Artificial drying secures the crop both in terms of quality and quantity and enables one to take measures in the event of damage to the standing crop (through storms, frost, and sanitary deterioration caused by Fusarium).

Harvest – Searching for the Compromise

| ADVANTAGES | DISADVANTAGES | |

| Harvesting too early | – limits losses – makes harvest operations easier – preserves soil structure – facilitates establishment of next crop |

– higher kernel losses per ear – more fragile kernels, more challenging machinery settings, clogging – additional drying costs – yield below maximum |

| Harvesting too late | – allows for easier threshing – saves up on drying costs |

– risk of unfavourable weather – increases risk of ground losses (cobs and/or kernels) – slow-down of harvest operations; risk of damage to soil structure – higher sanitary and agronomic (lodging) risks |

Although quality is not always related to kernel moisture content, ear moisture is directly correlated to kernel breaking and/or threshing, and therefore to the final quality of the whole and clean kernels being delivered.

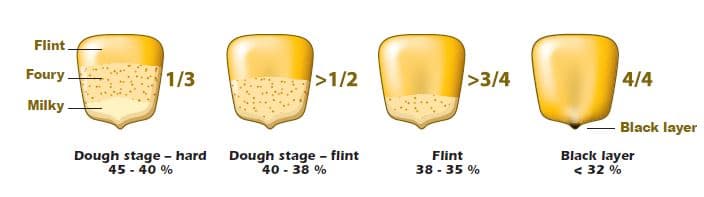

The crop reaches its optimum yield once the transfer of nutrients is finished – it is at this point that the thousand grain weight is at its maximum for the number of kernels present per square meter. This stage becomes noticeable when a black layer appears at the base of the kernel.

The Best Indicator: Field Observation

Modern maizes have made much progress in terms of exhibiting greater vigour at the end of their growth cycle. To visually determine the stage of the plants, one should rely on both kernels and the overall appearance of the plant’s vegetative body. To correctly assess the plants’ stage, one should:

– rely on the overall condition of the vegetative body, in order to ascertain the plants’ ability to function at the end of their life cycle and thus determine how much time one has before one can harvest past physiological maturity;

– monitor the kernel filling line down to the black layer (and/or the sum of temperatures), to find out the plants’ development stage.

When setting the harvest timing, one can never be too careful about observing the development stage of the standing plants.

Monitor grain filling

The Black Layer

The formation of the black layer is an indicator that nourishment to the kernel has ended. In hot years, when this process takes places normally, it can be a good indicator of the harvest date.

Warning! In cold years, the nourishment flow stops gradually and therefore can no longer be viewed as a reliable indicator.

Attaining the Quality Objective: the Three Steps

Quality refers to the kernels’ industrial qualities (physical characteristics and suitability for processing), as well as sanitary qualities (absence of mycotoxins otherwise generated by the presence of Fusarium spp. on cobs). Demand developments in terms of the marketing and sanitary qualities of maize have been such that access to market now depends on the crop’s production itinerary all the way from the field to primary processing. Each step along that technical itinerary must be carried out carefully in order to deliver a product that is wholesome, compliant to specifications, and marketable.

Quality Starts in the Field…

The technical choices one makes during the crop’s development will impact its quality. Thus the maturity stage (= the right balance between yield and moisture) is optimum when one chooses hybrids with growth rates that are adapted to their environment, as one needs to take advantage of the favourable drying conditions in the month of September.

• The maturity of the ears and their sanitary condition must be checked through field visits. This allows one to better predict the harvest date, select the plots to be harvested first – if necessary –, and helps ensure the traceability of the crop. Late plantings should be given particular attention, as they are more vulnerable to unfavourable weather, late harvesting, health risks, lodging, and frost damage.

• Harvests that take place early enough present a number of benefits (especially with maizes grown in rotations as wheat forerunners) and can also provide good opportunities for “linked marketing”[1].

• Kernel-filling and the kernel processing and health qualities are maintained when one is able to meet the plants’ water requirements, particularly before and after flowering.

• The sanitary condition of plants and kernels is ensured by a well-conceived sequence of agronomic practices from planting to harvest, especially in terms of corn borer control.

• The sanitary condition of the successive crop is improved when crop residues are chopped finely and incorporated into the topsoil.

[1] The notion designates one of the benefits of early planting, as the producer can anticipate selling their harvest and thus “make the link” between the previous year’s stocks and the stock from the new harvest. This provides a marketing opportunity to the producer, who can thus be a player on a market that is yet to be saturated by supply.

…Continues During Harvest…

The best conditions – both in terms of quantity and quality – are the combined result of:

• the farmer carefully determining the harvest date once the kernel reaches physiological maturity, has sufficiently low moisture content, and entails no field losses;

• the hybrid being suitable for threshing;

• the harvest contractor being able to harvest fast and with no losses to the farmer.

Recommended drying temperatures for maize based on moisture at harvest and grain destination

| Harvest moisture (%) | Duck & geese feed | Waxy maize | Maize starch industry | Livestock feed |

| 20-24 | 90-100 | 100-110 | 130-140 | 130-140 |

| 25-27 | 90-100 | 100-110 | 130-140 | 130-140 |

| 28-30 | 80-90 | 90-100 | 120-130 | 130-140 |

| 31-34 | 70-80 | 80-90 | 110-120 | 120-130 |

| 35-38 | 60-70 | 70-80 | 100-110 | 110-120 |

…and Is Maintained After Harvest.

While harvesting at maturity is the first quality prerequisite with maize, the conditions in which moist maize is received by the warehouse are equally important. Thus:

• Moist maize should not be left in storage for more than 24 hours. Also, it should be ventilated eventually by a strong jet of cool air (70-80 cubic metres/hour/cubic metre of kernels), in order to limit heating of kernels awaiting drying. One should equally make sure that the first amount in is also the first one dried and run a daily “zero point” check-up of awaiting cells.

• Drying conditions are then decisive for the kernels’ quality and processing suitability, as any deterioration risks damaging both their physical and marketing qualities, and indeed their use value. Drying that takes place at temperatures that are too high or that is done too brutally can therefore damage starch granules and proteins and reduces the use value of maize kernels – especially of those destined to the starch industry.

To conclude, hybrid selection will impact the quantity and quality of harvested grains, both directly (through the hybrids’ specific growth rates, genetic potential, and disease tolerance) and indirectly (through drought tolerance, resistance to lodging, and dry-down).